Editors note: This is part of a series of stories about innovative ways of recycling abandoned urban land in the Great Lakes region.

By Brendan McGaughey

CHICAGO- The nation’s largest urban solar plant, Exelon City Solar, is built on the ashes of an industrial site once contaminated by lead paint in the southside of Chicago.

This 41-acre brownfield property was home to the Pullman Railcar Co. from 1880 to 1955. A Dutch Boy paint factory followed. It closed in 1976 after polluting the ground. Then 30 years of non-use turned the site into an economic drain on the surrounding community.

Brownfield properties typically have been contaminated by an environmentally neglectful industry. Thousands exist nationwide.

And they are increasingly being overhauled into economic opportunities.

“Recycling is too often viewed as paper, glass and plastic,” said Henry Henderson, director of the Midwest Branch of the National Resources Defense Council. “We need to think of recycling the places we as humans decided to settle. Instead of being a burden on the surrounding communities, it would revitalize them.”

“Brownfields is an unfortunate name that carries a negative shadow with it,” said Henderson, Chicago’s founding commissioner of the environment and a former Illinois assistant attorney general. “All of these abandoned facilities sit in the middle of residential areas and are a drag on sustainable life. The question is how to clean up these properties and turn them into what I like to call ‘brightfields.’”

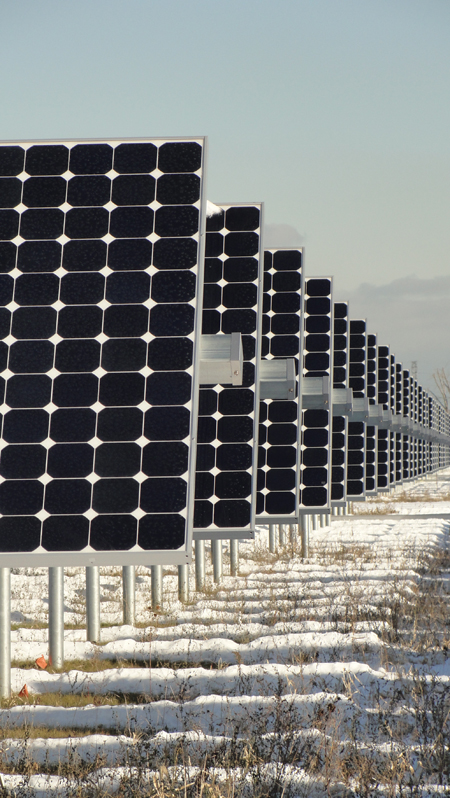

Exelon City Solar’s 32,292 solar panels generate more than 14,000 megawatt-hours of electricity per year. Photo: Brendan McGaughey

Brightfields, like Exelon City Solar, make developers aware of the exciting possibilities for a brownfield can become. Building a power plant in an undeveloped area and finding a way to get it on the grid for people to use can be very costly.

“The wisdom behind brownfield redevelopment is taking advantage of the existing infrastructure and market,” Henderson said. “People have a use for your product and you are near to them. It is an economical way to distribute energy.”

Exelon City Solar cost $60 million. It was dedicated on July 21, 2010, making it the largest urban solar power plant in the U.S. It’s capable of generating 10 megawatts of power, enough to meet the annual energy requirements for 1,500 homes.

“Part of the private sector’s attraction to redeveloping brownfields into useful clean energy installments is the existing infrastructure, which provides immediate access to the grid,” Henderson said.

Jobs are produced during the transformation into a brightfield.

Cleaning up the contamination to EPA standards and construction to the site created approximately 200 jobs, with at least half of the work hours completed by Chicago residents.

“When SunPower approached us it was something I never thought would work out,” said Greg DelCotto, vice president at Fabricating and Welding Corp. “Everything happened so fast, next thing you know we had a bid in for the job and got it.”

When Chicago’s 34th Ward Alderman Carrie Austin and people from SunPower approached DelCotto in Fall 2009, they quickly realized they could use Fabricating and Welding Corp.’s services after sending some work their way with a quick turn around.

“The job came at a good time when the economy went south, it carried us for a while,” DelCotto said. “It wasn’t a save all, but it definitely helped us.”

Fabricating and Welding Corp. manufactured more than 7,300 steel piers supporting the solar panels at Exelon Solar City. It’s a family owned 3rd generation steel fabrication industry that has been serving the industry for over 55 years.

EPA Brownfield Clean-Up

Each year the plant can capture the sun’s rays to generate enough energy to displace 31.2 million pounds of greenhouse gas emissions.

Greenhouse gases trap heat in the Earth’s atmosphere. They are emitted from burning fossil fuels and the combustion of materials. The Earth’s surface is warmer than it would be if the atmosphere didn’t contain these gases, so it creates a “greenhouse effect” according to the U.S. Environmental Protection Agency.

The site was plenty contaminated with lead and other hazardous materials.

“Once we crossed property lines, it was full hazmat suits with the boots and everything,” said Steve Robinette, a project superintendent with Riteway-Huggins Construction Services, Inc. “Sometimes if we were grinding concrete and a lot of dust was kicking up we had to wear masks. But we didn’t have any problems, the job went smoothly and it’s a real success as far as I’m concerned.”

To comply with Illinois standards contractors removed:

- 4,700 tons of soil, some visually stained

- Two 25,000-gallon underground storage tanks filled with soil and sand

- Three 55-gallon sealed drums containing solid waste

- A steel covered sump pit containing dirty ground water

- Insulation suspected of containing asbestos

But lead was the real problem. The Dutch Boy Paint factory closed in 1976. It changed hands many times before a suspicious fire in 1985.

The following year, tests revealed more than 300 people living near the plant suffered from varying degrees of lead poisoning. Some were sent to the hospital. Workers had to remove what EPA officials called “very hazardous levels of lead and asbestos,” according to a history of Chicago’s wards.

The factory was a real disaster and built up a lot of lead contamination on the site, Henderson said. People started dismantling the property in an unsafe and unsupervised way, which allowed contaminated lead dust to blow into the community.

Exelon City Solar is the largest urban solar power plant in the U.S. Photo: Brendan McGaughey

But Exelon saw an opportunity after an extensive examination of the site.

“We believed that cleaning up and redeveloping the site to generate environmentally friendly power would be a productive use of property that would likely have been dormant for years to come,” said Timothy Wirth, a spokesperson for Exelon Corp.

“We also saw this as an opportunity to help beautify and revitalize West Pullman, an area where industry once thrived,” Wirth said.

George Pullman built the historic Pullman neighborhood during the 1880s, which included his railroad car factory. The Pullman Palace Car Co. later manufactured streetcars and trolley buses. The Pullman factory built its last railcar in 1982 for Amtrak.

“You’re not going to change the energy economy overnight,” Henderson said. “But if you start investing into progressive projects such as brownfields, it is a way to rebuild the healthy fabric of communities.”

Henderson sees a great irony in people who own brownfield properties being afraid to invest in them. They fear they will be held responsible for all sorts of environmental contamination cleanup and fess, but really it’s worth the investment.

“Over $220,000 was spent to meet EPA environmental standards, $121,000 by the city of Chicago and $100,000 by Exelon,” Wirth said. “Exelon spent an additional $1.9 million to address brownfield issues.”

A significant value of the site is that it is in a population center.

Henderson recalls lots of discussions about building giant solar power installments in the middle of the Mojave Desert, but it would require massive transmission lines to reach the market. Also, the Dakotas are rich in wind, but have no existing infrastructure to channel it to the energy market.

These types of potential brightfield properties are valued because of their infrastructure.

“It helped that this property was close to where electricity is needed and existing transmission lines, but this may not be the case with all brownfields,” Wirth said.

“We also saw this as an opportunity to help beautify and revitalize West Pullman, an area where industry once thrived.” Wirth said.

Photo: Brendan McGaughey

More from this series:

- Great Lakes cities recycle brownfields into economic hope

- Buffalo brownfields link past industry to hope

-

Community support, diverse funds save historic building from demolition

-

Officials hope former truck factory helps make Michigan a movie star

- Federal loan brings employment hope to Wisconsin brownfields

- Detroit businessman proposes large scale commercial farm to struggling city

All 32,292 of these solar photovoltaic panels were made in Mexico.